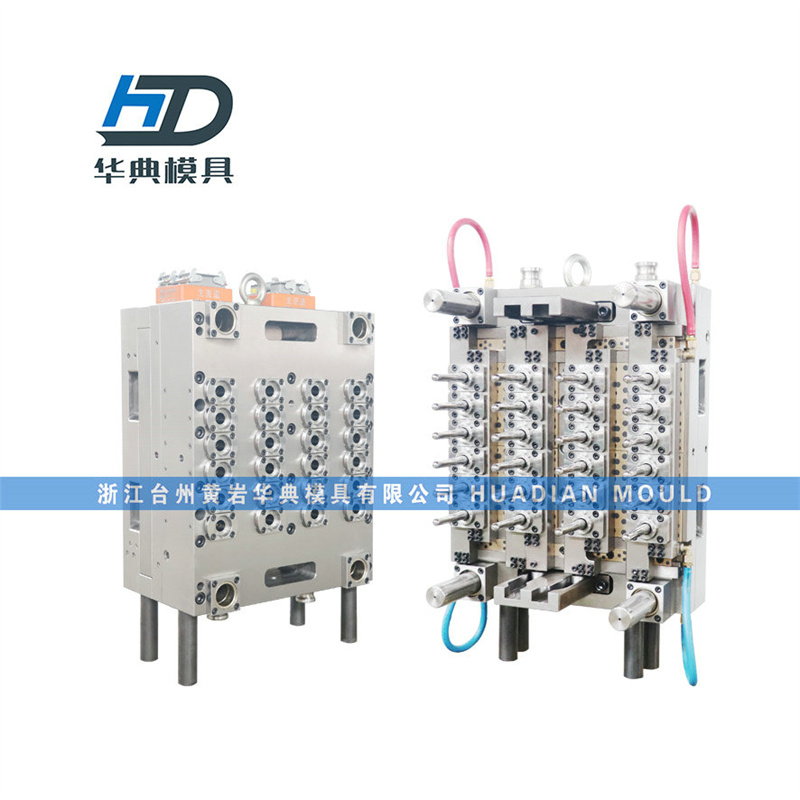

24 Cavities Disinfection Inoita Mold

Zvinotsanangurwa

| Cavity | Perform | Mold Kukura | Mold Weight | Cycle Time | |||

| Huremu(g) | Mutsipa(mm) | Urefu(mm) | Upamhi(mm)) | Hukobvu(mm) | (kg) | (sec) | |

| 2(1*2) | 720 | 55 | 470 | 300 | 608 | 330 | 125 |

| 4(2*2) | 720 | 55 | 490 | 480 | 730 | 440 | 130 |

| 8(2*4) | 16 | 28 | 450 | 350 | 410 | 475 | 18 |

| 12(2*6) | 16 | 28 | 600 | 350 | 415 | 625 | 18 |

| 16(2*8) | 21 | 28 | 730 | 380 | 445 | 690 | 22 |

| 24(3*8) | 28 | 28 | 770 | 460 | 457 | 1070 | 28 |

| 32(4*8) | 36 | 28 | 810 | 590 | 515 | 1590 | 28 |

| 48(4*12) | 36 | 28 | 1070 | 590 | 535 | 2286 | 30 |

Zvakanakira paHot Runner Technique

1. Deredza kutambisa uye mutengo wezvigadzirwa.

2. Deredza basa rekugadzirisazve, kupatsanura, kupwanya, kuomeswa, uye chitoro chemarara, kunatsiridza kushanda zvakanaka, kuchengetedza nguva nenzvimbo.

3.Dzivisa kushandisa zvinhu zvakadzorerwa izvo zvinokanganisa kunaka kwechigadzirwa.

4.Guarantee chigadzirwa muhutano hwakafanana

5.Kuwedzera jekiseni volum, Kuvandudza compressibiity epurasitiki kunyunguduka

6.Kuwedzera jekiseni basa, kuvandudza unyanzvi

7.Kuderedza nguva yejojo uye kudzvinyirira kuchengetedza

8.Reduce Clamping simba

9.Shorten Mold kuvhura sitiroko yejekiseni kushanda, Bvisa nguva yekutora iyo Nozzle zvinhu

10.Kupfupisa jekiseni kutenderera, kuvandudza otomatiki uye kushanda zvakanaka

Kuita kwakakosha kweHot Runner System

1.Kudzora kutonhora kwepurasitiki kunyunguduka zvakanyatsonaka, Bvisa kuora kwezvinhu.

2.Naturally balanced runner desgin, Mold Cavity yakaenzana yakazara.

3.Yakakodzera saizi yeHot Nozzle inogona kuve nechokwadi kuti plastiki inonyungudutsa mobile zvinobudirira uye mold cavity inozadzwa zvakaenzana.

4.Kururamisa gedhi chimiro uye saizi inogona kuvimbisa mold mugodhi zvakaenzana kuzadza, Tsono valve gedhi rakavharwa nenguva, kupfupisa kutenderera nguva.

5. Hapana kona yakafa mumhanyi, inshuwarisi yekushandura ruvara nekukurumidza, dzivisa kuparara kwezvinhu.

6. Kuderedza Kudzvinyirira kurasikirwa

7. Dzvinyiriro yekuchengetedza nguva inonzwisisika.

HuaDian Mold - mold data

| AIHWA. | Zita | Desciption | Kuoma | |

| 1 | Mold base material | P20 | 28-32 | |

| 2 | Core, cavity | S136 | 48-52 | |

| 3 | Mutsipa | S136 | 48-52 | |

| 4 | Kutonhodza mode | Mold core, mutsipa kutonhora | ||

| 5 | Kutonhodza mode ye core plate uye cavity plate | 1 mukati, 1 kunze | ||

| 6 | Kunze kwepakati(MM) | "+/-0.08MM | ||

| 7 | Cycle jekiseni nguva | 8-23 Sekondi | ||

| 8 | Delivery nguva | 55 Mazuva mushure medhizaini yakasimbiswa | ||

Iyo Yepamusoro inoshanda 24 cavity sterilizer mold ndeyemhando yepamusoro jekiseni mold yakagadzirwa nemhando yepamusoro simbi zvinhu zvine kusimba kwepamusoro uye kuita kwakavimbika.Ine majekiseni makumi maviri nemana akaumbwa mhango uye inogona kuburitsa makumi maviri nemana majekiseni panguva imwe chete, iyo inoshanda zvakanyanya kupfuura imwe mhango mold panguva imwe chete yekugadzira.

Pamusoro pezvo, mold inotora tekinoroji yepamusoro uye maitiro, kuitira kuti ive nekuvaka chaiko uye kuita kwakanakisa.Kunyangwe kana iri nyaya yekushanda kwesimba rakawanda, inovimbisawo kugadzikana kwekushanda uye inovandudza zvakanyanya kugadzirwa kwakanaka.

Iyo yepamusoro inoshanda 24 cavity sterilizer mold haina kukodzera chete kugadzirwa kwe sterilizer, asiwo yekugadzirwa kwezvimwe zvigadzirwa zvepurasitiki.Inogona kuiswa kune akasiyana mabhureki uye modhi yemajekiseni ekuumba muchina uye otomatiki mitsara yekugadzira, uye inogona zvakare kugadzirwa zvinoenderana nezvinodiwa nevatengi.

Pamusoro pezvo, mold haina chete mukana mukugadzirwa kwekugadzira, asi zvakare inogona kuderedza zvakanyanya mutengo wekugadzira uye kubatsira vatengi kuti vawedzere kukwikwidza pamberi pemakwikwi anotyisa emusika.Nekuda kweizvi, ndiyo imwe yesarudzo dzepamusoro kune vakawanda vagadziri uye makambani.